how do we choose between ring die and flat die pellet mills

The Difference Between Flat Die Pellet Mills And Ring Die Pellet Mills

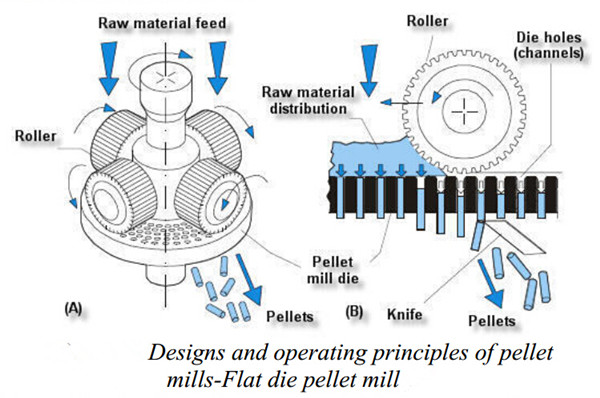

Generally pellet mills can be divided into two types: flat die mill and ring die mill. Flat die mills use a flat die with many holes. When the materials were introduced to the top of the die, the roller or the die could start rotating(depends on which type you chose, die turned or roller turned), and the materials would be pressed through the holes in the die. And a cutter on the other side of the die would cut the exposed pellets free from the die. Ring die mills use a ring die with radial slots. Materials are first fed into the inside of the die and distributed evenly by spreaders. Then they will be compressed through the die holes by two rollers, and the pellets come out of the die will be cut free by two cutters.

Because of its large capacity and high standard, ring die pellet mills are usually used to build large scale pellet making lines and pellet plants for industry or commercial business.

Compared to ring die mills, flat die mills have a simpler construction and a smaller capacity, and are much easier to operate. So the flat die mills are usually designed as small pellet mills for home use.

Ring Die

Flat Die

Why Do We Need Biomass Flat Die Pellet Mills

Our flat die pellet mills are categorized as small pellet mills, you can also call them household pellet mills or homemade pellet mills. The sizes and capacities of these pellet mills are suitable for small factories, farms and individual users.The flat die pellet mills produced by us can also be categorized as biomass pellet mills judged from the raw materials they use to produce pellets. A biomass pellet press is used to produce pellets as green energy resources. It can process many raw biomass materials such as wood, sawdust, bamboo, pine, alfalfa, straw, wheat bran, cotton stalk and rice husk. Pellets produced from these materials can be used as fuels for your hearths, stoves, ovens and BBQ grills. As a sort of biomass energy, they not only produce much less harmful gasses and smokes during their burning processes than regular fuels like woods or charcoal, but also have higher burning efficiency. So, with a biomass pellet mill, you can turn the fallen leaves at your door, mowed grass of your lawn or crop straws in your farm into high efficient green energy!

We provide four series of biomass flat die pellet mills: electric motor pellet mills, gasoline pellet mills, diesel pellet mills and PTO(power take off) pellet mills, each of them is powered by a different energy source. You can choose the best suited one for yourself.

Get In Touch